Retrofit

Buy new or bring your machine up to date?!

Whether you have an old or recent press/unit that you have issues with that forces you to accept the extra work it potentially carries out, too much cleaning and down time, ink/material waste due to inconsistency in the ink metering or you have to lower the speed because of vibrations or ghost print?

Retrofitting has proven a smart alternative because it brings the machine back to life at a fraction of the cost of a new machine and much faster as well. In the past fountain roller system was the main target for retrofit but focus today is stack presses and CI presses 5-20 years old.

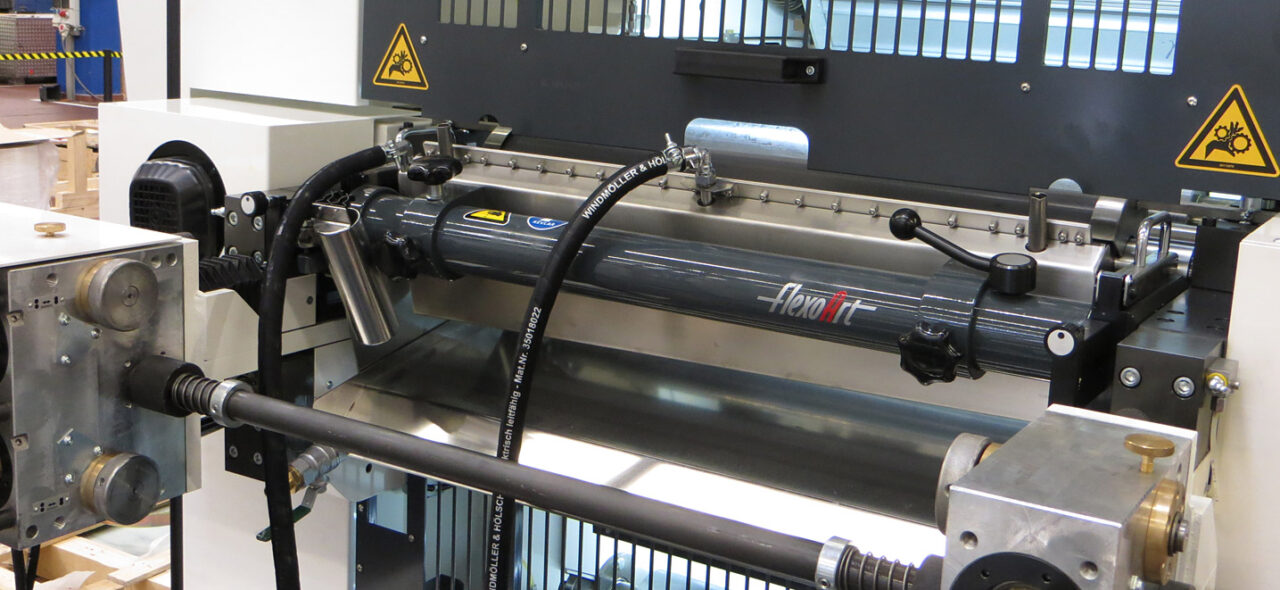

Converting your Flexo/varnish unit to FlexoArt doctor blade chamber system would not only give you control over the ink metering but also enables you to go up in speed, less cleaning and reduces the down time.

Thanks to our concept, the “low pressure chamber” and the patented suspension bar, the retrofit installation doesn’t need oversized hoses for ink and no pneumatics needed. We can get rid of lot of existing parts; this will increase the space and make easier handling of the machine itself.